Laminated Nonwoven Fabric

Home > laminated nonwoven fabric

Table Of Contents For This Page

It is not easy to introduce all complete information of spunbond non woven fabric, here we have classified the information that you may interested on this page. Please click the below content, and find the information which you are most interested. You also could detailed reading all the information from top to bottom on this page, which might take you about 10-20 minutes.

Hot Selling Prodcuts

Hefei Medpos is a leading manufacturer of sanitary material in China. With over 10 years experience and close cooperation with our partners, we can provide you all your needs with an affordable price! Our products include spunbond, SMS, spunlace non woven fabric, plastic films and PE laminated materials.

PE Laminated Spunbond Fabric

Material: Spunbond & PE

Size: 10-260cm

Weight: 25-200gsm

Color: Blue, White or Customzied

Type: Laminated With Glue or Without

Packing: As request

PE laminated spunbond fabric refers to spunbond nonwoven fabric that has been laminated with a layer of polyethylene (PE). Polyethylene is a versatile plastic known for its water resistance, durability, breathability and flexibility.

Widely used for Agriculture, furniture, bags, packing material, car, shoes, garmenthome textile, hospital, hygiene, industry, etc.

PE Laminated SMS Fabric

Material: SMS & PE

Size: 10-260cm

Weight: 25-200gsm

Color: Blue, Green, White or Customzied

Type: Laminated With Glue or Without

Packing: As request

Enhanced barrier properties: Protects against liquids, particles, and some microorganisms.

Increased strength and durability: The SMS structure provides good tensile strength.

Widely used for Agriculture, furniture, bags, packing material, car, shoes, garmenthome textile, hospital, hygiene, industry, etc.

SMPE Non-Woven Fabric

Material: Spunbond+Meltblown+PE

Size: 10-260cm

Weight: 50-200gsm

Color: Blue

Type: Ultrasonic Lamination

Packing: As request

Our SMPE non woven or SMSPE non woven, which is composed of high absorbent SM non woven or SMS non woven fabric and PE film laminated, is designed to absorb the liquid or blood quickly during the operation.

Widely used in manufacturing medical-grade protective apparel, such as surgical gowns and drapes, as well as high-performance filtration media.

Laminated Viscose Fabric

Material: Viscose + PE

Size: 10-260cm

Weight: 25-200gsm

Color: Blue, Green, White or Customzied

Type: Laminated With Glue or Without

Packing: As request

Viscose Nonwoven Fabric: Made from viscose fibers, which are derived from cellulose (typically wood pulp or cotton linters).

Known for its softness, absorbency, and biodegradability.

PE Lamination: A layer of polyethylene film applied to one or both sides of the viscose nonwoven fabric.

Widely used in medical and hygiene products such as surgical drapes, gowns, and disposable medical wipes, as well as in other fields where a combination of absorbency and barrier properties is required.

Laminated Spunlace Fabric

Material: Spunlace + PE

Size: 10-260cm

Weight: 25-200gsm

Color: White or Customzied

Type: Laminated With Glue or Without

Packing: As request

Spunlace Nonwoven Fabric: Also known as hydroentangled fabric

Made by entangling fibers using high-pressure water jets

Known for its soft texture, high strength, and cloth-like appearance

Can be made from various fibers, including polyester, viscose, or blends

PE Lamination: A layer of polyethylene film applied to one or both sides of the viscose nonwoven fabric.

Widely used in medical and hygiene products like surgical apparel, wipes, and industrial applications where a balance of absorbency and barrier protection is necessary.

All You Need to Know About Laminated Nonwoven

What is Laminated Non-woven Fabric?

Lamination nonwoven is the process of manufacturing a material in multiple layers, typically PE film laminated different nonwovens, such as PE+spunbond, PE+SMS, PE+Viscose ,PE+Spunlace, and SMSPE or SMPE. The combined physical and mechanical characteristics of each layer make for a stronger, more resilient composite material.

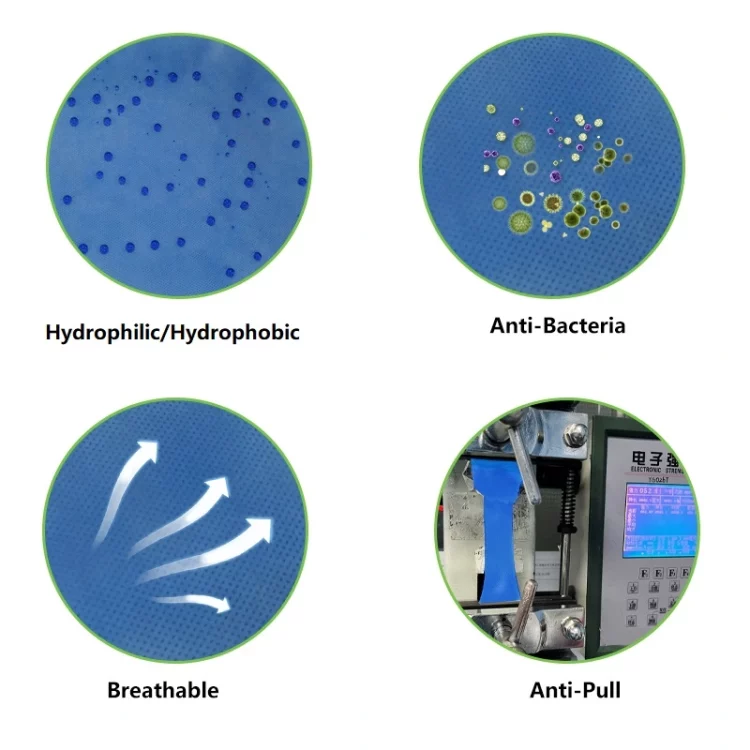

What Are The Characteristics of Laminated Non-woven Fabric?

Barrier Properties: Lamination enhances the fabric’s ability to resist liquids, gases, or particles, making it suitable for use in products requiring barrier protection, such as medical gowns, surgical drapes, and protective clothing.

Strength and Durability: The additional layer added through lamination improves the fabric’s tensile strength and tear resistance, increasing its durability and lifespan.

Water Resistance: Laminated nonwovens can be designed to repel water or liquids, making them ideal for use in products like diapers, sanitary napkins, and medical bedding where fluid resistance is crucial.

Customizability: Manufacturers can customize laminated nonwovens with various films, coatings, or layers to achieve specific performance requirements, such as antimicrobial properties, UV resistance, or breathability.

How Many Lamination Ways?

Hot Melt Lamination: Involves bonding a thermoplastic adhesive film to the nonwoven fabric using heat and pressure. This method is commonly used for applications requiring a strong bond and good flexibility.

Extrusion Lamination: A process where a molten polymer is extruded between the nonwoven fabric and a film, forming a strong bond upon cooling. It is used for applications requiring high barrier properties and strength.

Coating Lamination: Involves applying a liquid coating (such as polyurethane or acrylic) onto the nonwoven fabric. The coating is then cured or dried to form a bonded layer, providing specific performance enhancements like water resistance or breathability.

Adhesive Lamination: Uses an adhesive layer between the nonwoven fabric and another material (typically a film or another fabric). Adhesive lamination offers flexibility in bonding different types of materials and is widely used in textile and automotive industries.

Ultrasonic Lamination: Utilizes ultrasonic waves to bond layers of nonwoven fabric together without the need for adhesives or heat. This method is fast, energy-efficient, and suitable for sensitive materials or applications where maintaining material integrity is crucial.

What Is The Production Process of Laminated Non-woven Fabric?

1.Raw Material Selection

Nonwoven fabrics used as base materials are chosen based on their intended application and required characteristics such as strength, softness, and absorbency. Films or other materials for lamination are also selected based on their barrier properties, durability, and compatibility with the nonwoven.

2.Preparation of Materials

The nonwoven fabric and the lamination material (film, coating, adhesive) are prepared for the lamination process. This may involve cutting the materials to size, cleaning or treating them to ensure proper adhesion, and preparing any adhesive or coating materials.

3.Lamination Process

Hot Melt Lamination: The thermoplastic adhesive film is fed between heated rollers along with the nonwoven fabric. Pressure and heat bond the layers together, creating a strong laminate.

Extrusion Lamination: A molten polymer is extruded between the nonwoven fabric and a film, forming a strong bond upon cooling. This method is suitable for high barrier applications.

Coating Lamination: A liquid coating is applied onto the nonwoven fabric using techniques like roll coating, spraying, or immersion. The coated fabric is then cured or dried to form a bonded layer.

Adhesive Lamination: Adhesive is applied onto the nonwoven fabric or the bonding material (such as a film), and the layers are pressed together under controlled conditions to achieve a strong bond.

Ultrasonic Lamination: Ultrasonic waves are used to bond layers of nonwoven fabric together without adhesives or heat, providing a fast and energy-efficient method for certain applications.

4.Curing or Drying

Depending on the lamination method, the laminated material may undergo a curing process (for adhesive or coating lamination) or drying (for solvent-based coatings) to ensure proper bonding and remove any residual moisture.

5.Finishing and Quality Control

After lamination, the laminated nonwoven fabric may undergo additional finishing processes such as calendering (smoothing the surface), embossing (creating texture), or printing. Quality control measures ensure that the finished product meets specified standards for strength, barrier properties, softness, and other characteristics.

Applications

Packaging

Considerations When Bulk Purchase Laminated Non-woven

When bulk purchasing spunbond non-woven fabric, thorough research and due diligence are essential. Focus on material specifications, supplier reliability, quality standards, and application requirements while also considering cost, logistics, and environmental factors. This comprehensive approach will help ensure you select the right product and supplier for your needs. Here are elaborations of some key considerations:

1. Material Specifications

•GSM (Grams per Square Meter): Determines the fabric’s weight and thickness. Higher GSM indicates a thicker and stronger fabric.

•Material Composition: Commonly polypropylene, but other materials like polyester or polyethylene might be used depending on the application.

2. Quality and Standards

•Manufacturing Standards: Ensure the fabric meets industry standards and certifications.

•Quality Control: Verify the manufacturer’s quality control processes and request quality certificates or test reports.

3. Supplier Reliability

•Production Capacity: Ensure the supplier can meet your bulk order requirements within the desired timeframe.

•Sample Request: Obtain samples before placing a large order to verify quality and suitability.

4. Technical Properties

•Strength and Durability: Confirm the fabric’s tensile strength, tear resistance, and durability.

•Permeability: Ensure the fabric meets your needs for breathability and moisture vapor transmission.

•Barrier Properties: Assess resistance to water, chemicals, and other potential contaminants if applicable.

5. Application Requirements

•Intended Use: Match the fabric’s specifications to the specific requirements of your application, whether it’s for medical, agricultural, industrial, or hygiene use.

•Customization: Determine if the supplier offers customization options such as specific sizes, colors, or treatments (e.g., anti-bacterial, anti-static).

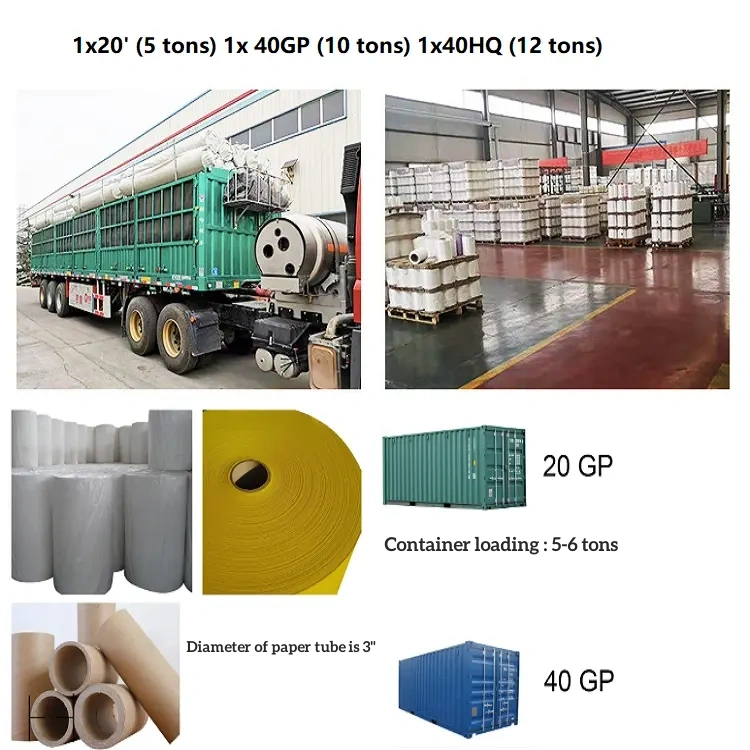

6. Cost and Logistics

•Pricing: Compare prices from multiple suppliers, considering not just the cost per unit but also shipping and handling fees.

•Minimum Order Quantity (MOQ): Ensure the supplier’s MOQ aligns with your needs.

•Delivery Time and Logistics: Confirm lead times, shipping options, and logistics arrangements to ensure timely delivery..

7. Environmental Considerations

•Sustainability: Inquire about eco-friendly options or recycled materials if sustainability is a priority.

•Disposal and Recycling: Understand the disposal and recycling options for the fabric after use.

With more than 10 years’ production and export experience in the sanitary material field, we are pround to say all requirements above are statisfied by Medpos. We are always providing stable and competitive price, consistent quality, on time delivery, 24/7 timely response and professional service. And we will make efforts to minimize your purchasing and shipping costs and provide options for your choice if need.

Work Process & Duration Estimation

Working with Medpos will be more efficient. We only take your 1% time to finish 20% of your workload!

Inquiry & Quote (1~3days)

After receiving customer inquiry and studying requirements, we will provide with an accurate quotation within 24 hours. Prices are generally valid for 20 days due to fluctuation of raw materials.

Samples (3-7days)

We have stock sample for normal width and weight in small quantity. For custmoized samples, it takes 3-7 days to produce according customer need such as weight, width and physical performance.

Bulk Production (15-30 days)

Our bulk production time is generally 15 to 30 days. Raw material normally takes 5 to 10 days. After the material arrives at the factory, our quality inspection department will inspect materials at first, then start mass production after passing the test.

Secondlly, we will make pre-production sample to ensure quality in line with customer requirements.

Thirdly, during mass production, our quality inspection department will also conduct several random inspections. The bulk production time is around 10-15 days.

At last, our quality inspection department will conduct the last inspection when mass production is finished.

Delivery (1 day)

Once production approved by our end or the third party. We will make the shipment immediately to ensure client receiving the goods at the earliest time.

A Brief Self-Nomination ,Why Choose Hefei Medpos?

Hefei Medpos is a specialized manufacturer and exporter of sanitary material of non woven fabric and plastic films. Not only providing you with customized solutions, but also providing you with an incredible full range of end-to-end services to make everything easier.

- Superior Quality Control

- Compliance and Certification

- Innovative Product Development

- Cost Efficiency

- Sustainability Initiatives

- Reliability and Consistency

- Exceptional Customer Service

- Advanced Manufacturing Capabilities

- Performance and Innovation

- Transparent Communication

The FAQs About Laminated Non-woven Fabric

Explore these common queries about spunbond nonwoven fabric. Contact us for further assistance!

Absolutely! Our team of expert provide OEM on request. We will work closely with you to ensure the material aligns with your application and meets your specific requirements.

We offer low MOQ standards to accommodate businesses of all sizes. Please contact us to discuss your specific requirements and we will provide you with a customized quote.

Absolutely! We provide samples to help you evaluate the quality and suitability of our laminated nonwoven fabric for your application. Please contact us to request samples and discuss your specific needs.

Quality is ensured through stringent quality control processes, including regular testing for strength, durability, weight, and other key parameters. Our manufacturing facilities are equipped with advanced technology to maintain consistent quality across all batches.

Our team of experts is committed to providing excellent customer service and support throughout the entire process. If you have any questions or concerns after placing your order, please do not hesitate to reach out to us.

We have a robust supply chain management system and large-scale production capabilities to handle large orders efficiently. We work closely with our logistics partners to ensure timely delivery and provide regular updates on order status.

Don't hesitate contact with us, send mail

Contact us to get a free quote and more expertise about disposable underpad. Your project will meet a right solution with Medpos.

- We will contact you within 12 hours

- Don't worry, we hate spam too!